In today’s fast-paced business landscape, optimizing inventory management is crucial for staying ahead of the competition. By defining clear objectives, you’ll unlock the door to reduced costs, improved efficiency, and enhanced customer satisfaction. But where do you start? This article will explore the essential goals to target, helping you create a tailored roadmap for inventory optimization success. Let’s dive in!

“Taking Stock: Assessing Your Current Inventory Management Process”

Before optimizing your inventory management, you need to understand how it’s working – or not. Think of it like trying to navigate a new city without a map. You might know where you want to go, but you need to understand the layout of the streets to get there. inventory optimization

Let’s say you’re the inventory manager at a bustling retail store. You notice that you’re stuck with a surplus of seasonal items that didn’t sell as expected every quarter. Meanwhile, your fastest-selling products are frequently out of stock. This is a classic sign of a bottleneck in your inventory management process. inventory optimization

To identify these bottlenecks, take a step back and assess your current process. Ask yourself:

- What are our current inventory management procedures?

- Where are the pain points in our process?

- What are the consequences of these bottlenecks (e.g., stockouts, overstocking, delayed shipments)?

For example, a company like Patagonia, which prides itself on sustainability, might identify a bottleneck in its supply chain due to inconsistent lead times from environmentally friendly suppliers. By recognizing this issue, they can start exploring solutions like diversifying their supplier base or implementing a more flexible inventory management system.

By taking the time to understand your current process and pinpoint areas for improvement, you’ll be able to create a tailored plan to optimize your inventory management and achieve your objectives.

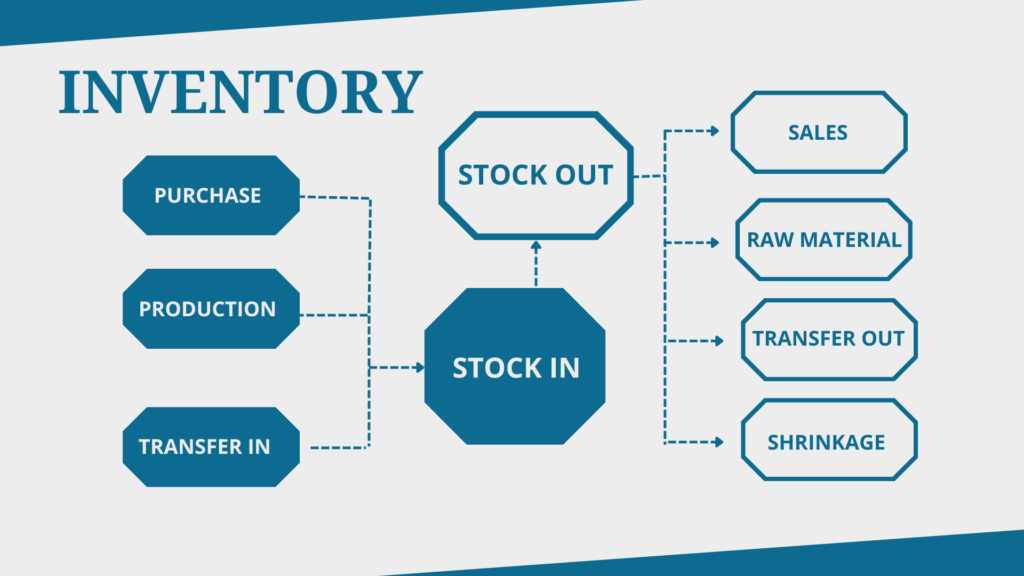

“Prioritizing What Matters: Segmenting and Categorizing Your Inventory”

Imagine you’re a chef, and your inventory is the ingredients in your pantry. You wouldn’t manage your spices the same way you manage your meat, right? Some items are more critical to your dishes than others. It’s the same with your inventory. inventory optimization

Segmenting and categorizing your inventory helps you focus on what matters. By grouping items by value, usage, and importance, you’ll be able to:

- Identify the items that drive the most revenue or customer satisfaction

- Allocate resources more effectively

- Make informed decisions about inventory levels and replenishment

Let’s say you’re the inventory manager at a hospital. You might categorize your inventory into:

- Critical care items (e.g., life-saving medications, surgical equipment)

- High-usage items (e.g., gloves, syringes)

- Low-value items (e.g., paper towels, cleaning supplies)

By prioritizing critical care items, you ensure that essential supplies are always available. Meanwhile, you can implement just-in-time ordering for high-usage items to minimize waste and reduce storage needs. inventory optimization

Another example is a fashion retailer like Zara, which segments its inventory into:

- Fast-selling, high-value items (e.g., trendy clothing, limited-edition collections)

- Slow-selling, low-value items (e.g., basic t-shirts, socks)

By focusing on fast-selling items, Zara can quickly respond to changing fashion trends and customer demand.

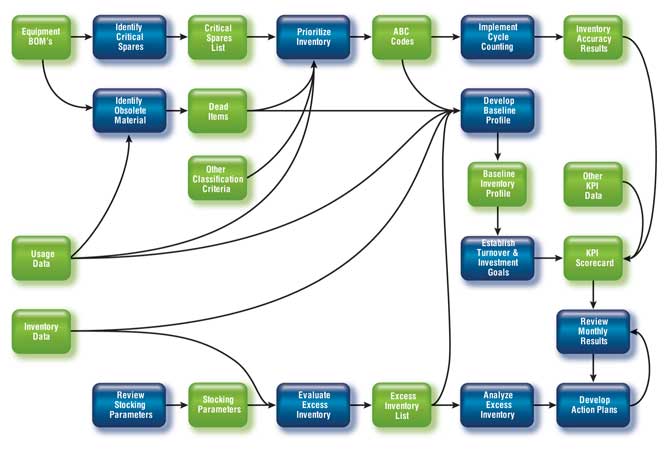

The ABC Analysis

A simple way to segment your inventory is by using the ABC analysis:

- A (High value, high usage): Prioritize these items for optimization efforts

- B (Medium value, medium usage): Monitor and adjust inventory levels regularly

- C (Low value, low usage): Consider outsourcing or reducing inventory levels

By segmenting and categorizing your inventory, you’ll be able to tailor your optimization strategy to what drives your business.

“Finding the Sweet Spot: Setting Optimal Inventory Levels”

Imagine you’re a coffee shop owner, and you’re trying to determine how much coffee to stock. If you stock too little, you’ll run out and disappoint customers. If you stock too much, you’ll waste money and storage space. Finding the ideal balance is crucial. inventory optimization

Setting optimal inventory levels involves considering several factors:

Demand: How much of each item do customers want?

Lead time: How long does it take to restock or replenish inventory?

Storage capacity: How much space do you have to store inventory?

Supplier reliability: Can you count on your suppliers to deliver on time?

Seasonal fluctuations: Do demand patterns change throughout the year?

Let’s say you’re the inventory manager at an outdoor gear store. You notice that demand for camping equipment spikes in the summer months. To prepare, you increase inventory levels of tents, sleeping bags, and backpacks during the spring. However, you also consider the lead time for restocking, which is 6-8 weeks, to ensure you don’t run out during the peak season. inventory optimization

Another example is a company like Amazon, which uses advanced algorithms to predict demand and adjust inventory levels accordingly. They also consider factors like storage capacity and supplier reliability to ensure they can meet customer demand while minimizing waste. inventory optimization

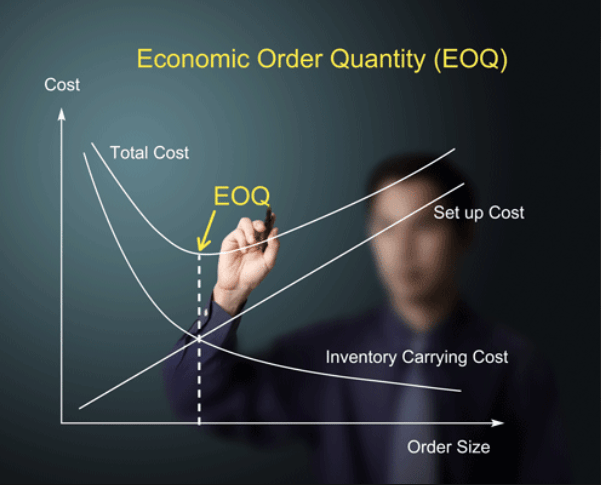

The EOQ Formula

A simple way to calculate optimal inventory levels is by using the Economic Order Quantity (EOQ) formula:

EOQ = √(2 x Demand x Ordering Cost) / Holding Cost

Where:

- Demand is the average annual demand

- Ordering Cost is the cost of placing an order

- Holding Cost is the cost of storing an item

By considering these factors and using tools like the EOQ formula, you’ll be able to find the sweet spot for your inventory levels.

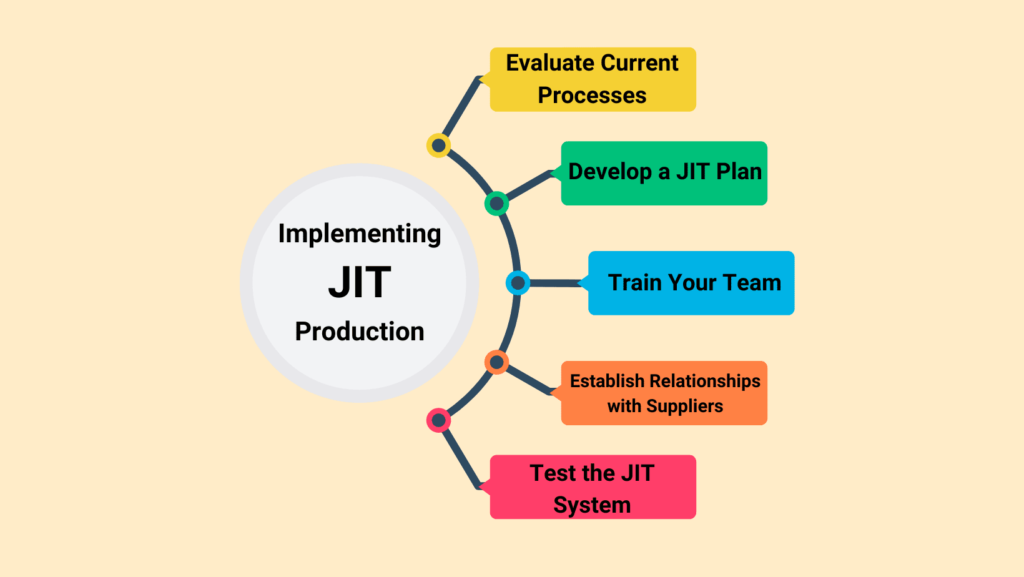

“Streamlining Your Inventory: Implementing JIT, EOQ, and VMI Strategies”

Imagine you’re a master chef, and your kitchen is your inventory management system. You want to ensure that every ingredient is fresh, readily available, and used at the right moment. That’s where Just-In-Time (JIT), Economic Order Quantity (EOQ), and Vendor-Managed Inventory (VMI) strategies come in – to help you cook up a lean and efficient inventory management process. inventory optimization

Just-In-Time (JIT)

JIT is like cooking for a dinner party. You prepare only what’s needed, just in time. This strategy ensures you have minimal inventory on hand, reducing waste and storage needs. inventory optimization

Example: A company like Dell uses JIT to manage its computer components. They order and receive parts just in time to assemble and ship products to customers.

Economic Order Quantity (EOQ)

EOQ is like buying spices in bulk. You calculate the optimal quantity to purchase, considering demand and storage space.

Example: A retailer like Walmart uses EOQ to determine the ideal order quantity for its products, balancing inventory costs with customer demand. inventory optimization

Vendor-Managed Inventory (VMI)

VMI is like having a personal grocery shopper. Your supplier manages your inventory levels, ensuring you have what you need when you need it.

Example: A company like Procter & Gamble uses VMI with its suppliers, who monitor and replenish inventory levels automatically. inventory optimization

By implementing these strategies, you’ll be able to:

- Reduce inventory costs and waste

- Improve supplier relationships

- Increase efficiency and productivity

- Enhance customer satisfaction

Real-Life Success Story

A company like Toyota has mastered JIT and VMI strategies, achieving incredible efficiency in its supply chain. By working closely with suppliers and implementing lean inventory management practices, Toyota has reduced inventory costs and improved delivery times. inventory optimization

“Unlocking Insights: Leveraging Technology for Inventory Optimization”

Imagine you’re a detective, and your inventory is the mystery to be solved. You need clues to crack the case of optimization. That’s where technology comes in – to provide the insights you need to make informed decisions. inventory optimization

Inventory Management Software

This is like having a trusty sidekick, keeping track of every move in your inventory. Software like TradeGecko, Zoho Inventory, or Skubana helps you:

- Track inventory levels in real-time

- Automate ordering and reporting

- Analyze sales trends and forecast demand

Example: A company like Warby Parker uses inventory management software to track its trendy eyewear inventory, ensuring that customers can always find their favorite frames. inventory optimization

Barcode Scanning

This is like having a superpower, scanning and tracking inventory with ease. Barcode scanning helps you:

- Quickly identify and track inventory items

- Automate inventory counting and reporting

- Reduce errors and improve accuracy

Example: A company like Amazon uses barcode scanning to manage its vast inventory, ensuring fast and accurate order fulfillment. inventory optimization

Data Analysis

This is like having a crystal ball, revealing insights into your inventory’s future. Data analysis helps you:

- Identify trends and patterns in sales and inventory

- Forecast demand and optimize inventory levels

- Make data-driven decisions to improve efficiency

Example: A company like Coca-Cola uses data analysis to optimize its inventory management, ensuring that the right products are in the right place at the right time. inventory optimization

By leveraging these technologies, you’ll be able to:

- Gain real-time visibility into your inventory

- Make data-driven decisions

- Improve efficiency and reduce costs

- Enhance customer satisfaction

Real-Life Success Story

A company like Walmart has implemented a robust inventory management system, using data analysis and machine learning to optimize its inventory levels. By leveraging technology, Walmart has reduced inventory costs and improved supply chain efficiency. inventory optimization

“Staying on Track: Monitoring and Adjusting Your Inventory Optimization Strategy”

Imagine you’re a navigator, charting a course through the ever-changing waters of inventory management. To stay on track, you need to continuously monitor your progress, identify trends, and make adjustments as needed. inventory optimization

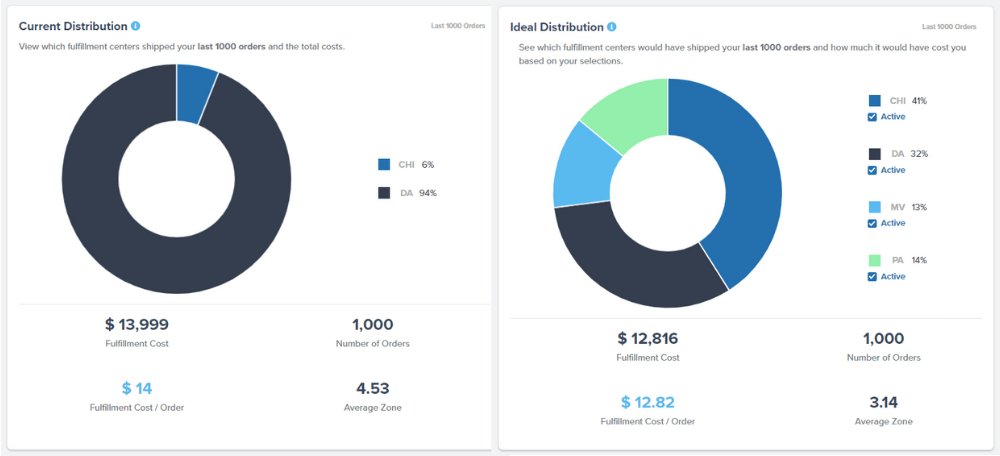

Track Key Performance Indicators (KPIs)

This is like checking your map to ensure you’re on course. KPIs like inventory turnover, fill rates, and stockout rates help you:

- Measure the effectiveness of your inventory optimization strategy

- Identify areas for improvement

- Make data-driven decisions

Example: A company like Apple tracks its inventory turnover rate to ensure that products are selling quickly and efficiently.

Analyze Trends and Seasonality

This is like recognizing patterns in the weather. Analyzing trends and seasonality helps you:

- Identify fluctuations in demand

- Adjust inventory levels accordingly

- Stay ahead of the competition

Example: A company like Home Depot analyzes sales trends to anticipate increased demand for seasonal items like patio furniture and holiday decorations. inventory optimization

Make Adjustments as Needed

This is like adjusting your sails to catch the wind. Making adjustments as needed helps you:

- Respond to changes in demand or supply

- Optimize inventory levels for new products or promotions

- Stay agile in a rapidly changing market

Example: A company like Amazon adjusts its inventory levels and shipping strategies during peak holiday seasons to ensure fast and reliable delivery. inventory optimization

By continuously monitoring and adjusting your inventory optimization strategy, you’ll be able to:

- Stay ahead of the competition

- Improve customer satisfaction

- Reduce costs and improve efficiency

- Drive business growth

Real-Life Success Story

A company like Domino’s Pizza has implemented a robust inventory management system, continuously monitoring and adjusting its inventory levels to ensure that customers receive their favorite pizzas quickly and efficiently. By staying on track, Domino’s has improved customer satisfaction and driven business growth. inventory optimization

“Simplifying the Flow: Streamlining Storage, Picking, and Shipping Processes”

Imagine you’re a conductor, orchestrating the movement of inventory through your warehouse. To create a harmonious flow, you need to streamline storage, picking, and shipping processes, reducing waste and improving efficiency.

Optimize Storage Layout

This is like arranging the orchestra seats. A well-designed storage layout helps you:

- Maximize warehouse space

- Reduce travel time for pickers

- Improve inventory accessibility

Example: A company like IKEA uses a compact storage layout to minimize warehouse space and reduce costs.

Implement Efficient Picking Methods

This is like choreographing the pickers’ dance. Efficient picking methods like zone picking, wave picking, or batch picking help you:

- Reduce picking errors

- Increase picking speed

- Improve order fulfillment rates

Example: A company like Amazon uses robotic picking assistants to streamline the picking process and improve efficiency.

Simplify Shipping Processes

This is like coordinating the grand finale. Simplifying shipping processes helps you:

- Reduce shipping errors

- Increase shipping speed

- Improve customer satisfaction

Example: A company like UPS uses automated shipping systems to streamline the shipping process and reduce errors.

By streamlining storage, picking, and shipping processes, you’ll be able to:

- Reduce waste and improve efficiency

- Improve customer satisfaction

- Increase productivity and reduce labor costs

- Drive business growth

Real-Life Success Story

A company like Walmart has implemented a streamlined warehouse management system, reducing waste and improving efficiency in its storage, picking, and shipping processes. By simplifying the flow, Walmart has improved customer satisfaction and driven business growth.

“Staying Ahead of the Curve: Embracing Change and Continuous Improvement”

Imagine you’re a sailor, navigating the ever-changing waters of the market. To stay on course, you need to stay up-to-date with changing market conditions, customer needs, and new technologies, ensuring ongoing improvement and optimization.

Monitor Market Trends

This is like scanning the horizon for changes in the weather. Monitoring market trends helps you:

- Anticipate shifts in demand

- Adjust inventory levels accordingly

- Stay ahead of the competition

Example: A company like Netflix continuously monitors market trends, adjusting its content offerings to meet changing customer preferences.

Listen to Customer Feedback

This is like tuning in to the radio for updates on changing weather patterns. Listening to customer feedback helps you:

- Identify areas for improvement

- Make data-driven decisions

- Enhance customer satisfaction

Example: A company like Amazon uses customer feedback to improve its product offerings, services, and overall customer experience.

Embrace New Technologies

This is like upgrading your navigation system to stay on course. Embracing new technologies helps you:

- Improve efficiency and productivity

- Enhance inventory management

- Stay competitive in a rapidly changing market

Example: A company like Walmart has implemented AI-powered inventory management systems to improve efficiency and reduce costs.

By staying up-to-date with changing market conditions, customer needs, and new technologies, you’ll be able to:

- Drive business growth and improvement

- Enhance customer satisfaction

- Stay ahead of the competition

- Navigate the ever-changing market with confidence

Real-Life Success Story

A company like Airbnb has continuously evolved its platform to meet changing customer needs and market conditions, embracing new technologies and innovations to stay ahead of the competition.

Pingback: Deep Dream Generator - aitechverge.com