“Welcome to the world of heavy lifting! A chain block, also known as a hand chain hoist, is a powerful and versatile tool used to lift and move heavy loads with ease. From construction sites to factories, chain blocks are essential equipment for many industries. But have you ever wondered how they work and what makes them so effective? Let’s dive in and explore the definition and purpose of a chain block, and discover why it’s a game-changer for anyone who needs to lift heavy loads safely and efficiently.”

From Humble Beginnings to Heavy Lifting

The chain block has a rich history that dates back to the early 19th century. The first chain blocks were developed in the 1800s in England, where they were used in shipyards and docks to lift heavy loads. These early chain blocks were made of simple pulleys and chains, but they paved the way for the modern chain blocks we use today. Chain block

In the late 1800s, chain blocks became a crucial tool in the construction of iconic landmarks like the Brooklyn Bridge in New York. Workers used chain blocks to lift massive steel beams into place, revolutionizing the construction industry. Chain block

Fast forward to World War II, chain blocks played a vital role in the war effort. They were used in shipyards to build warships and in factories to produce military equipment. The war pushed the development of chain blocks further, leading to the creation of more robust and efficient models. Chain block

Today, chain blocks are used in a wide range of industries, from manufacturing to oil rigging. They’ve come a long way from their humble beginnings, but their core purpose remains the same: to lift heavy loads safely and efficiently. Chain block

Here’s an example of how chain blocks are used in real life:

- The construction of the Burj Khalifa, the world’s tallest building, relied heavily on chain blocks to lift massive concrete slabs into place.

The evolution of chain blocks is a testament to human ingenuity and the need to push boundaries. As technology advances, chain blocks continue to improve, making them an indispensable tool for industries around the world. Chain block

The Anatomy of a Chain Block

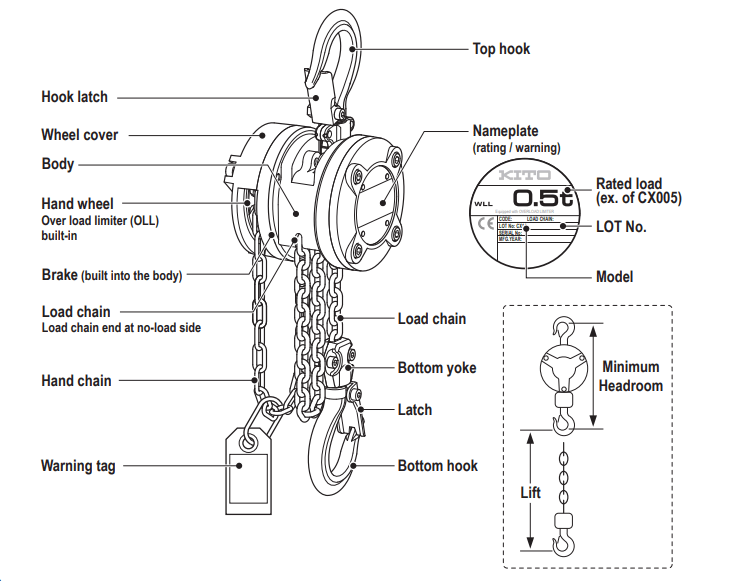

A chain block is made up of several key components that work together to lift heavy loads. Let’s break down the different parts and explore how they contribute to the overall functionality of a chain block. Chain block

1. Chain

The chain is the backbone of a chain block. Made from high-strength steel, the chain is designed to withstand heavy loads and harsh environments. The chain is typically made up of small, interlocking links that allow it to flex and move smoothly over the wheels. Chain block

Example: Imagine a construction worker using a chain block to lift a heavy steel beam. The chain wraps around the beam, providing a secure grip that won’t slip or fail. Chain block

2. Wheels

The wheels, also known as pulleys, are the round components that the chain wraps around. They’re designed to reduce friction and allow the chain to move smoothly, making it easier to lift heavy loads.

Example: Picture a factory worker using a chain block to lift a heavy crate. The wheels spin smoothly as the worker pulls the chain, making it easy to lift the crate off the ground. Chain block

3. Hook

The hook is the metal attachment at the end of the chain that secures the load. It’s designed to be strong and durable, with a safety latch to prevent the load from accidentally slipping off.

Example: Think of a stagehand using a chain block to lift a heavy lighting rig. The hook securely attaches to the rig, allowing the stagehand to lift it safely into place. Chain block

4. Hand Chain

The hand chain is the long, looped chain that the operator uses to pull the chain block. It’s designed to be comfortable to grip and easy to pull, even with heavy loads.

Example: Imagine a mechanic using a chain block to lift a heavy engine. The hand chain allows them to pull the engine up into the air, giving them the clearance they need to work underneath. Chain block

5. Load Plate

The load plate is the metal plate that attaches to the hook, providing a flat surface for the load to sit on. It’s designed to distribute the weight of the load evenly, preventing damage to the chain or hook.

Example: Picture a warehouse worker using a chain block to lift a heavy pallet. The load plate provides a stable surface for the pallet to sit on, ensuring it doesn’t slip or fall off during lifting. Chain block

These are the main components that make up a chain block. By understanding how each part works together, you’ll be better equipped to use a chain block safely and effectively. Chain block

The Chain Block Family: Manual, Electric, and Beyond

Chain blocks come in a range of flavors, each designed to suit specific needs and industries. Let’s explore the different types of chain blocks and how they’re used in real-life scenarios. Chain block

Manual Chain Blocks

Manual chain blocks are the most common type and rely on human power to lift loads. They’re simple, reliable, and cost-effective.

Example: Meet Jane, a maintenance worker at a manufacturing plant. She uses a manual chain block to lift heavy machinery parts into place for repair. With a few pulls on the hand chain, she can lift a 500-pound gearbox with ease. Chain block

Electric Chain Blocks

Electric chain blocks, also known as electric hoists, use an electric motor to lift loads. They’re faster and more efficient than manual chain blocks, making them ideal for heavy-duty applications.

Example: Imagine a team of construction workers building a high-rise building. They use an electric chain block to lift heavy concrete slabs into place, speeding up the construction process. Chain block

Hydraulic Chain Blocks

Hydraulic chain blocks use hydraulic fluid to lift loads, providing a smooth and precise lift. They’re commonly used in heavy industries like shipbuilding and oil rigging.

Example: Picture a team of shipbuilders using a hydraulic chain block to lift a massive propeller into place. The hydraulic system ensures a smooth and controlled lift, reducing the risk of damage or injury. Chain block

Pneumatic Chain Blocks

Pneumatic chain blocks use compressed air to lift loads, making them ideal for industries where electricity is not available or safe.

Example: Meet a team of miners using a pneumatic chain block to lift heavy equipment into place. The compressed air system allows them to work safely in explosive environments. Chain block

Specialized Chain Blocks

There are also specialized chain blocks designed for specific industries, such as food processing, clean rooms, and explosive environments.

Example: Imagine a food processing plant using a stainless steel chain block to lift heavy equipment into place. The stainless steel construction ensures a sanitary and corrosion-free environment. Chain block

Each type of chain block has its unique features and applications. By choosing the right type of chain block, industries can improve efficiency, safety, and productivity. Chain block

The Science Behind the Lift: How Chain Blocks Work

Have you ever wondered how a chain block can lift massive loads with such ease? It’s all about the clever use of pulleys, levers, and mechanics. Let’s dive into the inner workings of a chain block and explore how it gets the job done. Chain block

The Pulley System

A chain block consists of two main pulleys: the anchor pulley and the load pulley. The anchor pulley is fixed in place, while the load pulley moves up and down as the chain is pulled.

Example: Imagine a construction worker using a chain block to lift a heavy concrete slab. As they pull the chain, the load pulley moves up, lifting the slab off the ground. Chain block

The Mechanical Advantage

The chain block uses a mechanical advantage to amplify the force applied to the chain. This means that a small force applied to the chain can lift a much heavier load.

Example: Picture a mechanic using a chain block to lift a heavy engine. They apply a small force to the chain, but the mechanical advantage of the chain block allows them to lift the engine with ease. Chain block

The Chain and Hook

The chain wraps around the pulleys and attaches to the hook, which secures the load. The chain is designed to flex and move smoothly over the pulleys, reducing friction and wear.

Example: Imagine a stagehand using a chain block to lift a heavy lighting rig. The chain wraps around the pulleys and attaches to the hook, securely lifting the rig into place.

The Hand Chain

The hand chain is the long, looped chain that the operator uses to pull the chain block. It’s designed to be comfortable to grip and easy to pull, even with heavy loads.

Example: Picture a warehouse worker using a chain block to lift a heavy pallet. They pull the hand chain, which lifts the pallet off the ground, making it easy to move around the warehouse.

By understanding how a chain block works, you’ll appreciate the clever mechanics that make it possible to lift heavy loads with relative ease.

Chain Blocks in Action: Industries and Situations

Chain blocks are versatile lifting tools that can be found in various industries and situations. From construction sites to factories, chain blocks play a crucial role in lifting heavy loads safely and efficiently. Let’s explore some of the industries and situations where chain blocks are commonly used.

Construction

Chain blocks are a staple on construction sites, used for lifting heavy building materials like concrete slabs, steel beams, and pipes.

Example: Meet John, a construction worker building a new skyscraper. He uses a chain block to lift heavy concrete slabs into place, ensuring a safe and efficient construction process.

Manufacturing

In factories, chain blocks are used to lift heavy machinery, equipment, and products, streamlining production processes.

Example: Picture Maria, a factory worker assembling heavy machinery. She uses a chain block to lift the machinery into place, making it easier to assemble and repair.

Shipping and Logistics

Chain blocks are used in ports and warehouses to lift heavy cargo, containers, and pallets, facilitating the loading and unloading of goods.

Example: Imagine Ahmed, a dockworker loading cargo onto a ship. He uses a chain block to lift heavy containers into place, ensuring a safe and efficient loading process.

Oil and Gas

In the oil and gas industry, chain blocks are used to lift heavy equipment, pipes, and machinery, supporting drilling and extraction operations.

Example: Meet Sarah, an oil rig worker lifting heavy pipes into place. She uses a chain block to ensure a safe and efficient lifting process, even in harsh environments.

Entertainment

Chain blocks are also used in the entertainment industry, lifting heavy lighting rigs, speakers, and stage equipment for concerts and events.

Example: Picture Jack, a stagehand setting up for a concert. He uses a chain block to lift heavy lighting rigs into place, ensuring a safe and efficient setup process.

These are just a few examples of industries and situations where chain blocks are commonly used. By understanding the diverse applications of chain blocks, you’ll appreciate their versatility and importance in various industries.

Safety First: Precautions and Considerations When Using Chain Blocks

Chain blocks are powerful lifting tools, but they can also be dangerous if not used properly. It’s crucial to prioritize safety when working with chain blocks to prevent accidents and injuries. Let’s explore some important safety considerations and precautions to keep in mind.

Proper Training

Before using a chain block, ensure you’ve received proper training on its operation, maintenance, and safety procedures.

Example: Meet Emily, a new factory worker who’s been trained on-chain block safety and operation. She confidently uses the chain block to lift heavy equipment, knowing she’s taking the necessary precautions.

Regular Maintenance

Regularly inspect and maintain chain blocks to ensure they’re in good working condition. Check for worn or damaged chains, hooks, and pulleys, and replace them as needed.

Example: Picture David, a construction worker who regularly inspects his chain block before use. He notices a worn chain and replaces it, ensuring a safe lift.

Load Capacity

Never exceed the recommended load capacity of a chain block. Overloading can lead to accidents and damage to the equipment.

Example: Imagine a stagehand trying to lift a heavy lighting rig with a chain block. They check the load capacity and realize it’s too heavy, so they use a larger chain block instead.

Proper Rigging

Ensure proper rigging techniques are used when lifting loads with a chain block. This includes using the correct hook and sling configurations.

Example: Meet James, a dockworker lifting a heavy container with a chain block. He uses the correct rigging techniques to ensure a safe and secure lift.

Personal Protective Equipment

Always wear personal protective equipment (PPE) when using chain blocks, including hard hats, gloves, and safety glasses.

Example: Picture a mechanic using a chain block to lift a heavy engine. They wear PPE to protect themselves from potentially falling objects or debris.

By prioritizing safety and following these precautions, you’ll be able to use chain blocks with confidence and minimize the risk of accidents.

Keeping it Running Smoothly: Tips for Chain Block Maintenance

Chain blocks are reliable lifting tools, but they require regular maintenance to ensure they continue to run smoothly and safely. Proper upkeep can extend the lifespan of your chain block and prevent costly repairs. Let’s dive into some tips for maintaining your chain block.

Regular Inspections

Regularly inspect your chain block for signs of wear and damage. Check for rust, corrosion, and worn or damaged chains, hooks, and pulleys.

Example: Meet Michael, a factory worker who inspects his chain block daily. He notices a small crack in the hook and replaces it before it becomes a bigger issue.

Cleanliness

Keep your chain block clean and free of debris. Regularly wash the chain and components with soap and water, and dry thoroughly.

Example: Picture Emily, a construction worker who washes her chain block after each use. She ensures it’s dry before storing it away, preventing rust and corrosion.

Lubrication

Regularly lubricate moving parts, such as pulleys and bearings, to keep them running smoothly.

Example: Meet David, a mechanic who lubricates his chain block’s pulleys and bearings every month. He ensures smooth operation and prevents wear and tear.

Storage

Properly store your chain block when not in use. Keep it in a dry, clean area away from direct sunlight and moisture.

Example: Imagine James, a dockworker who stores his chain block in a dry container after each use. He ensures it’s secure and protected from the elements.

Record Keeping

Keep records of maintenance, inspections, and repairs. This helps track the chain block’s history and ensures compliance with safety regulations.

Example: Picture Maria, a factory supervisor who keeps detailed records of chain block maintenance. She ensures her team is aware of the chain block’s history and can plan for future maintenance.

By following these tips, you’ll be able to keep your chain block in top condition, ensuring safe and efficient lifting operations.

The Advantages of Chain Blocks: Versatility, Durability, and More

Chain blocks are a popular lifting tool in various industries, and for good reason. They offer a range of benefits that make them an essential piece of equipment for many professionals. Let’s explore some of the advantages of using chain blocks.

Versatility

Chain blocks are incredibly versatile and suitable for lifting a wide range of loads, from heavy machinery to delicate equipment.

Example: Meet Sarah, a stagehand who uses a chain block to lift heavy lighting rigs and delicate sound equipment. She appreciates the versatility of her chain block, which allows her to lift loads of various sizes and weights.

Durability

Chain blocks are built to last, with durable materials and construction that can withstand heavy use and harsh environments.

Example: Picture John, a construction worker who uses his chain block daily to lift heavy building materials. He’s impressed with its durability, which has withstood the rigors of frequent use and harsh weather conditions.

Chain blocks are relatively easy to use, with simple operation and minimal setup required.

Example: Meet Emily, a factory worker who uses a chain block to lift heavy equipment. She finds it easy to operate, even with heavy loads, and appreciates the minimal setup required.

Cost-Effective

Chain blocks are a cost-effective lifting solution, offering a high lifting capacity at a lower cost than other lifting tools.

Example: Imagine David, a mechanic who uses a chain block to lift heavy engines. He finds it more cost-effective than other lifting tools, which allows him to stay within his budget.

Safety

Chain blocks are designed with safety in mind, offering a secure lifting solution that minimizes the risk of accidents.

Example: Picture Maria, a dockworker who uses a chain block to lift heavy containers. She appreciates the safety features of her chain block, which gives her peace of mind when lifting heavy loads.

By understanding the benefits of chain blocks, you’ll appreciate why they’re a popular choice among professionals who need a reliable and versatile lifting tool.

The Power of Chain Blocks: A Summary and Final Thoughts

Chain blocks are a crucial tool in various industries, offering a reliable and efficient way to lift heavy loads. Let’s summarize the key points and reflect on the importance of chain blocks.

Key Points:

- Chain blocks are versatile lifting tools used in construction, manufacturing, shipping, and more.

- They consist of a chain, pulleys, and a hook, with manual or electric operation.

- Regular maintenance and inspections are crucial for safe and efficient operation.

- Chain blocks offer benefits like versatility, durability, ease of use, cost-effectiveness, and safety.

Final Thoughts:

Chain blocks are more than just a lifting tool – they’re a trusted partner in getting the job done. They’ve helped build iconic structures, enabled efficient manufacturing processes, and facilitated global trade.

Example: Meet Jane, a construction worker who used a chain block to lift heavy steel beams during the construction of a new skyscraper. She reflects, “That chain block was our lifeline – we couldn’t have done it without it!”

Conclusion:

Chain blocks are a testament to human ingenuity and the need for efficient lifting solutions. By understanding their importance and proper use, we can harness their full potential and achieve great things.

Pingback: Digital Transformation Consultancy - aitechverge.com